We had a good amount of progress over the last two days. I also forgot to mention a few things in my 10-day recap post from the 28th, so I'll put those down at the bottom.

Build continued to work on pieces and were able to complete four more. We now have seven pieces completed and still around 37% of pieces in progress. Some of the mill pieces for the drivetrain were finished although there are still more to complete. We should get a good amount of pieces (and hopefully the full drivetrain assembled) finished over the weekend as we have a lot of time to work. In addition, some slight hitches with CNC will hopefully be ironed out tomorrow and, once we are able to ensure that pieces be made safely and effectively on the CNC, we will be able to use the new 1/8" bits that arrived to make a good chunk of the robot pieces on the CNC. As usual, the plan is for the robot to be assembled by the end of next Sunday.

Electrical has started working on the electrical board and pneumatic systems and, if the parts ordered arrive on time, they should be finished. Depending on the build finish time (the way it's looking from the sheer volume of parts to be made), electrical might have to wire the robot after next weekend. Although, if we are able to use our resources and time to our advantage, a full wiring is still possible by the end of next weekend.

Software has the drivetrain code completed and is working on operator controls as well as some basic tracking for the port and balls. They are now also working on rudimentary autonomous. In theory, we should be able to have a good autonomous using simply our encoders and pre-programmed instructions. However, it would be nice - and this is the goal we are striving towards this year - to have an autonomous mode that uses limelight and sensor input to be able to continue driving and scoring based on what it's already done. That would allow us not only to use the full fifteen seconds to our advantage (as opposed to just shooting three balls in and stopping for ten seconds) but also to hopefully score more points.

Marketing has finished first drafts for the chairman's presentation and Woodie Flowers essay and will be reviewing tomorrow. They will also finish the first drafts of the Dean's List essays during the weekend so that there is sufficient time for review of all the awards.

As I said before, there are a couple of things I forgot to mention in the recap. One of them was a collection of handy pictures of the robot climbing (in the CAD). As design finished, Beni was able to capture all the possible robot climbing configurations and make sure they work and that we can climb.

Pictured above you can see every possible climb configuration for our robot.

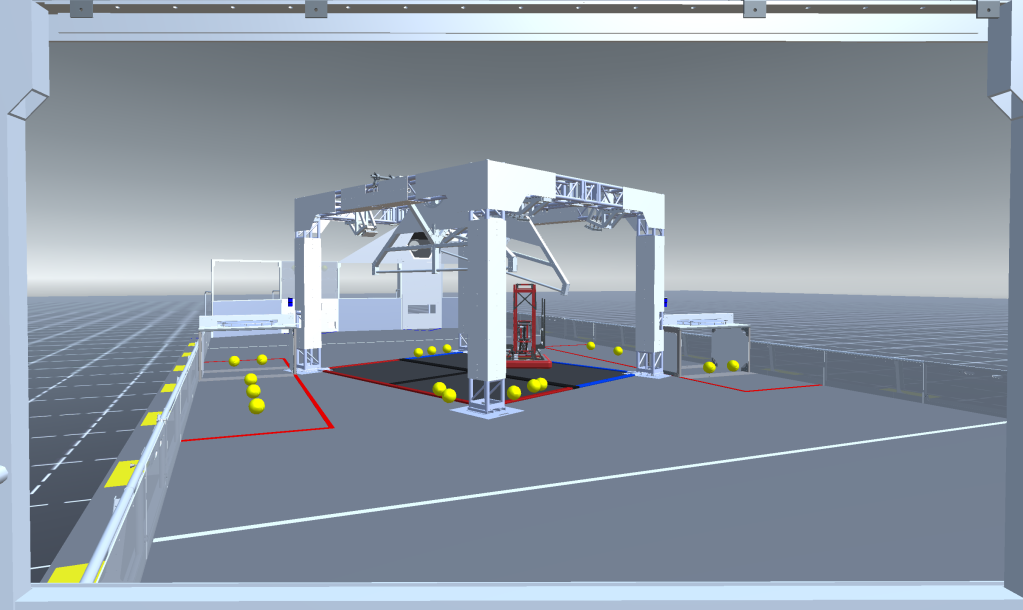

I also opened up a program called Synthesis which lets you input robot CAD and code and test it virtually on your computer. From there I could get a somewhat realistic representation of the view that we would see from each driver station.

The view from each driver station with a sample robot loaded in the middle.

From the three views we can see that the drive team view of the port is very minimal if visible at all and that the angle at which we view the scale is definitely not optimal. This would mean that, in order to be relatively effective at scoring and climbing, we would most likely need an automated adjustment system for shooting that uses limelight to align as well as an adjustment mechanism for the scale that would let the drive team have greater error in lining up for the climb.

The last thing I forgot to recap was our work with the intake prototype. We tested this out last Saturday when we got the 2" mecanum wheels from West Coast Products. These proved to be difficult to work with due to their limited slanted roller coverage. This meant we needed to bunch them up very closely for the slanted rollers to have coverage on the ball. We also had some trouble with actually getting the mecanum wheels to center the ball. Below you can see the problem we had where they would essentially act as normal wheels and squish the ball to intake it.

The mecanum wheel problem we had for pretty much all of Saturday.

Every once in a while we would get the intake to kind of work, but this success was usually very short and the results could not be replicated. Below is one instance where we saw the intake working.

The intake seems to work for a bit, but then reverts to the problem in the video before this.

We ended Saturday pretty disappointed but hopeful for what the new mecanum wheels (which we had marked as superior to the WCP ones and which we bought on Sunday) could bring us. And, lo and behold, when the new mecanum wheels arrived on Wednesday, our intake somehow magically worked. For one, the better slanted roller coverage allowed us to spread them farther apart and still have good coverage on the ball. In addition, we got the spacing pretty good and the intake seemed to work well. Below you can see it with the new wheels, spaced out quite a bit.

The intake working for the first time.

As you may have noticed, the last two ball throws bounced off because they hit a bit of a dead spot in the intake. We were easily able to resolve the problem by bring the wheels slightly closer and basically eliminating that dead zone while still keeping some distance between the wheels. Below you can see the revised (and so far the best) version we have right now.

The intake at its best.

The primary purposes of building an intake prototype were to make sure the concept works and to make sure balls don't jam when we try to pick up multiple at the same time. We should hopefully be getting more balls within the next couple of days and, when we do, we will test out the possibility of jamming. Although this won't be a perfect representation of the robot geometry, it should still give us a good idea of what we have to work with. You can see full videos of the intake (the ones above are only small clips) in the photos/videos album on the front page.

That basically concludes the recap from the past ten days and the progress from the last two. There will be more blog posts over the weekend as the teams come in to do their various jobs.

Comments

Post a Comment