Hello team,

Over the last two days more notable progress was made as the first week of the build season came to an end.

Build continued to construct the field pieces and are remarkably close to being finished. Today the shield generator piece was completed with the exception of six small pieces. Other than those six pieces and the curved slots on the human player station, all the field elements are complete. Although a little behind schedule, the build team was still able to complete the pieces relatively quickly so that we have a full field ready.

Two pictures of the finished top port. Unfortunately there isn't a picture of the climb bar currently.

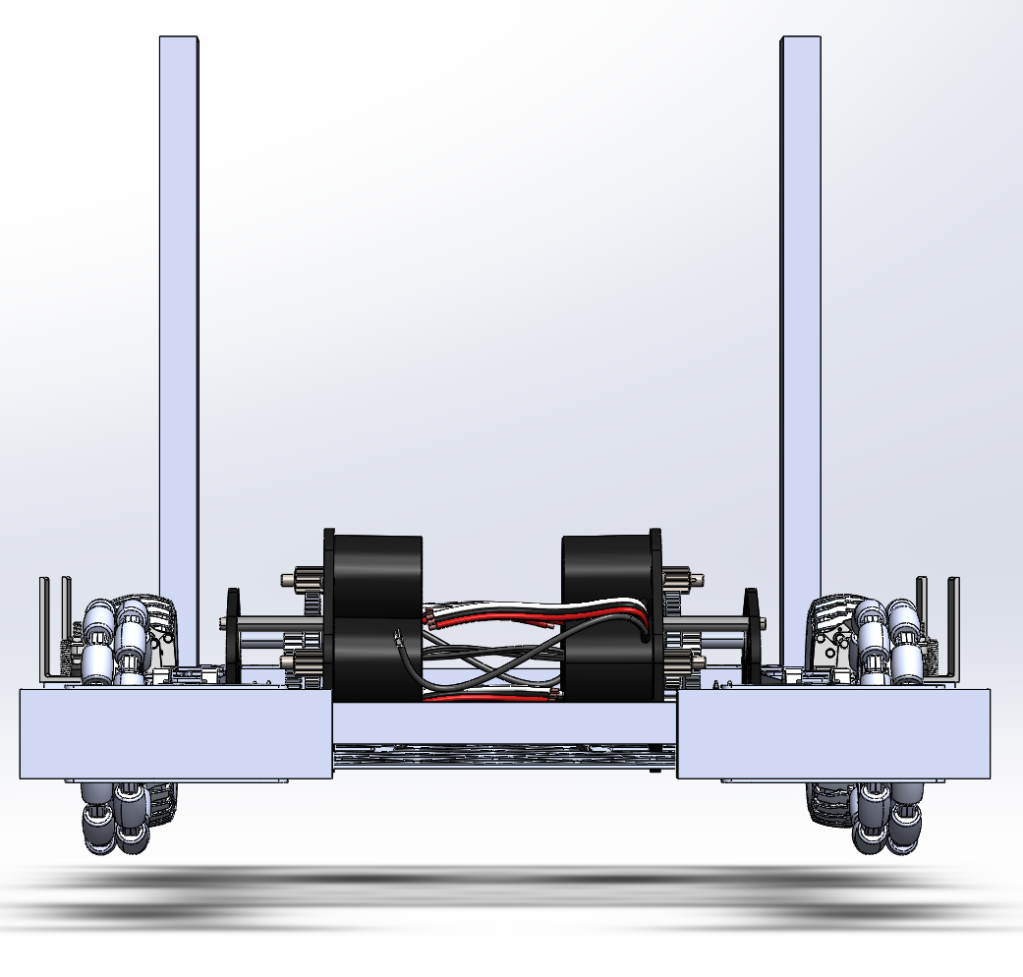

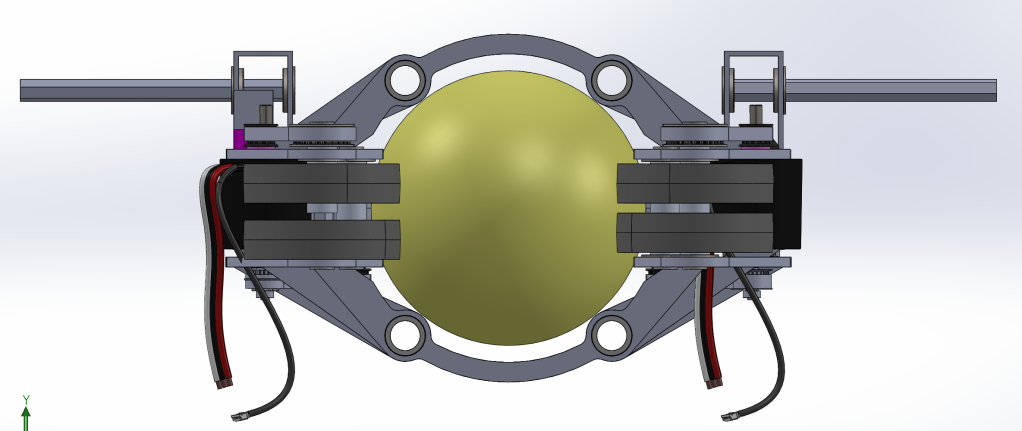

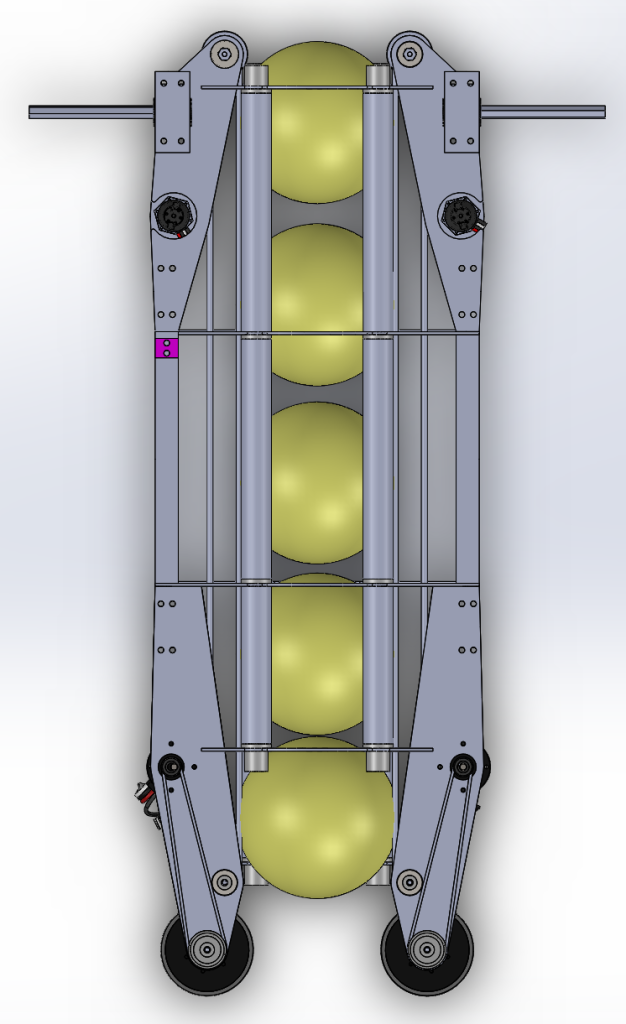

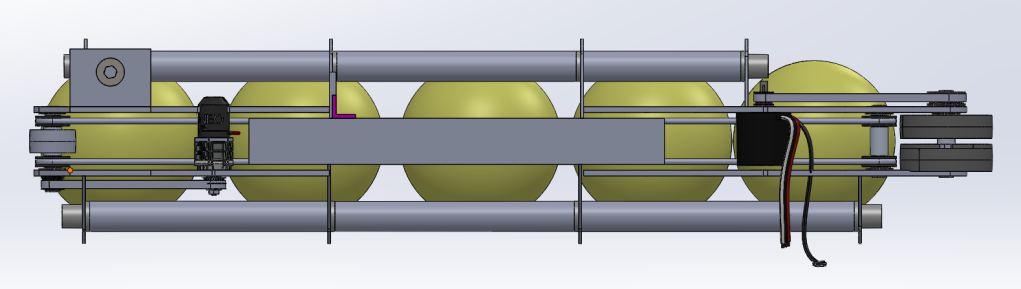

Design had great progress with the initial stages of CAD. The drivetrain design and ball transfer tube design are almost finished and only a few small additions need to be made. Work on the elevator, intake, and color wheel mechanism will begin soon. Design seems right on schedule to meet the several deadlines they have next week.

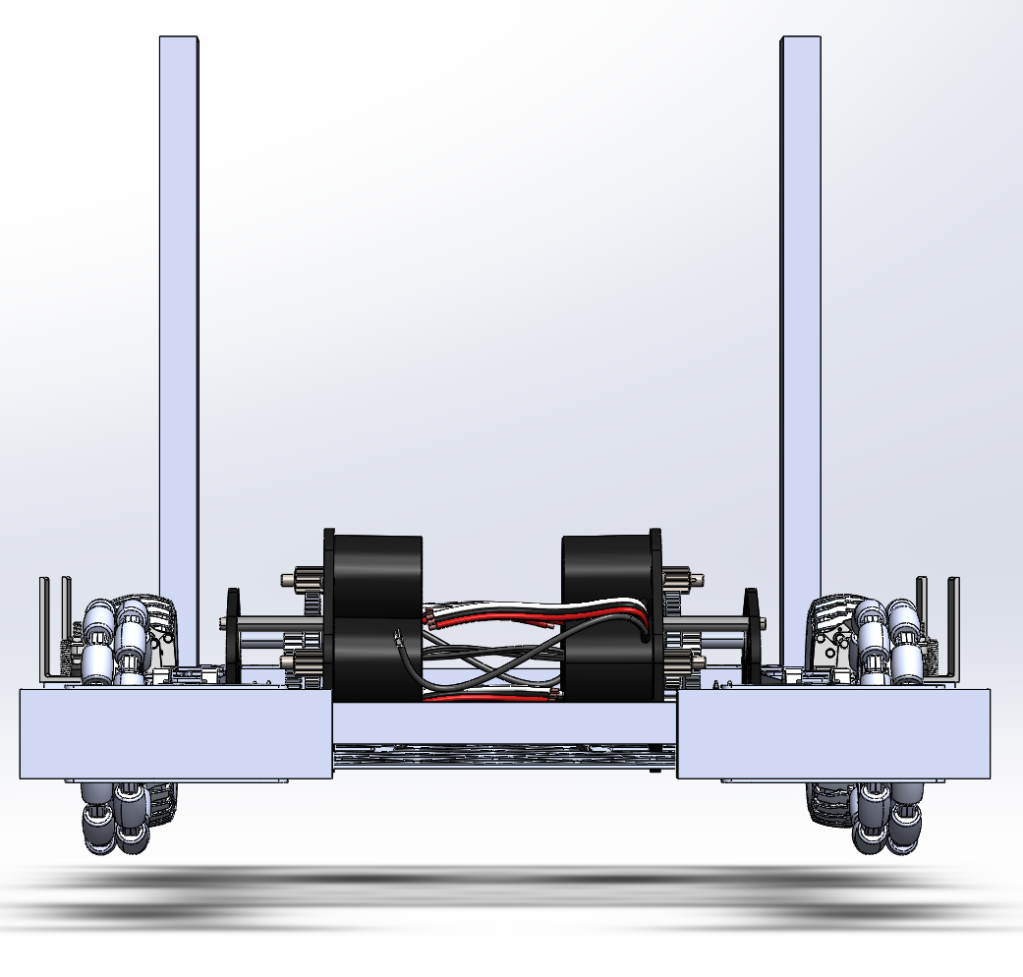

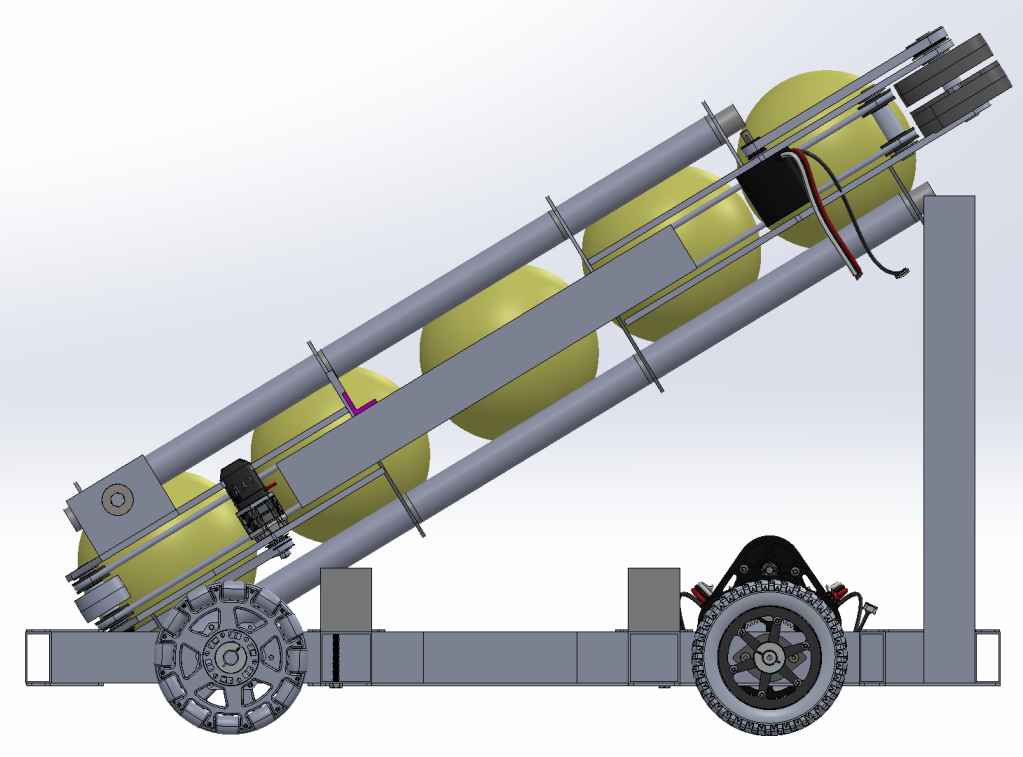

Pictures of the drivetrain right now.

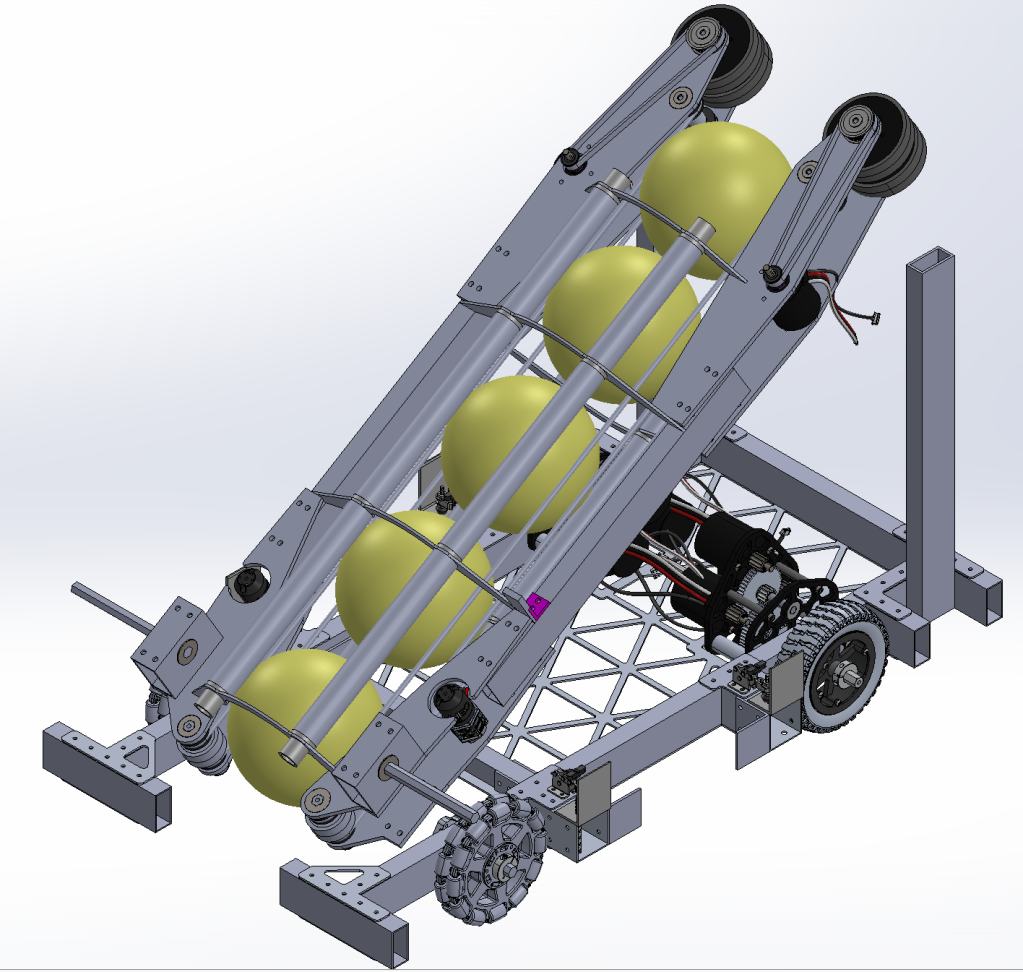

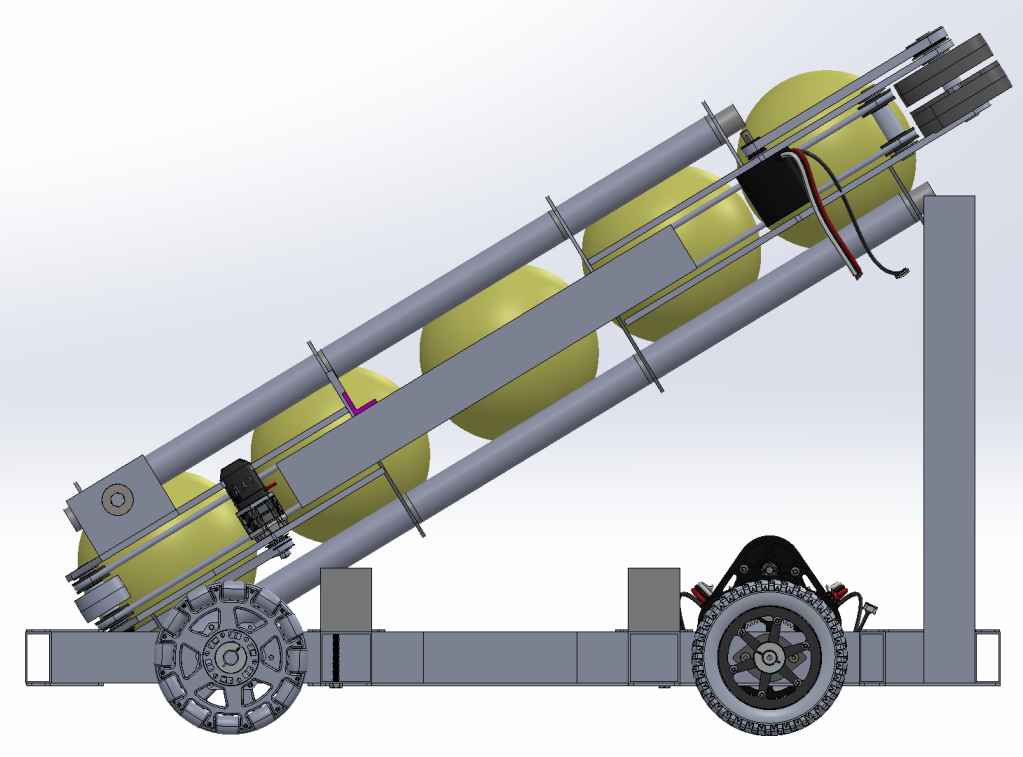

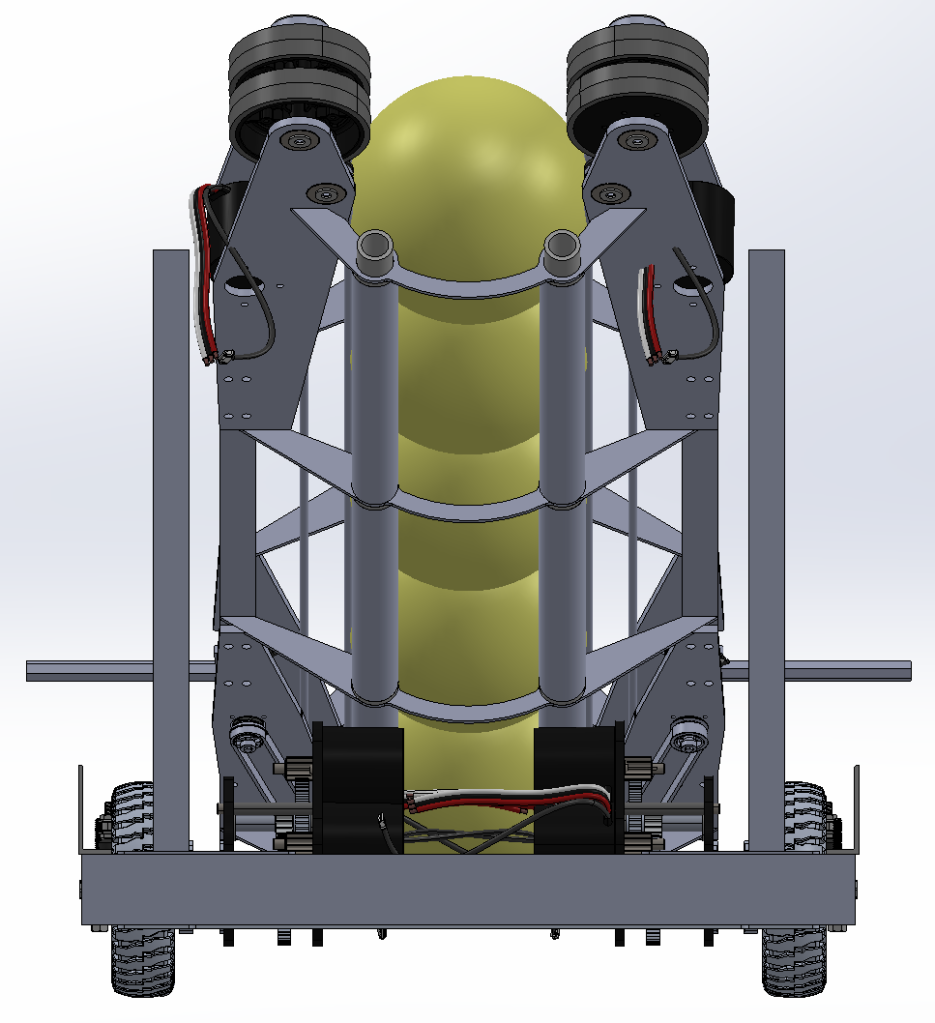

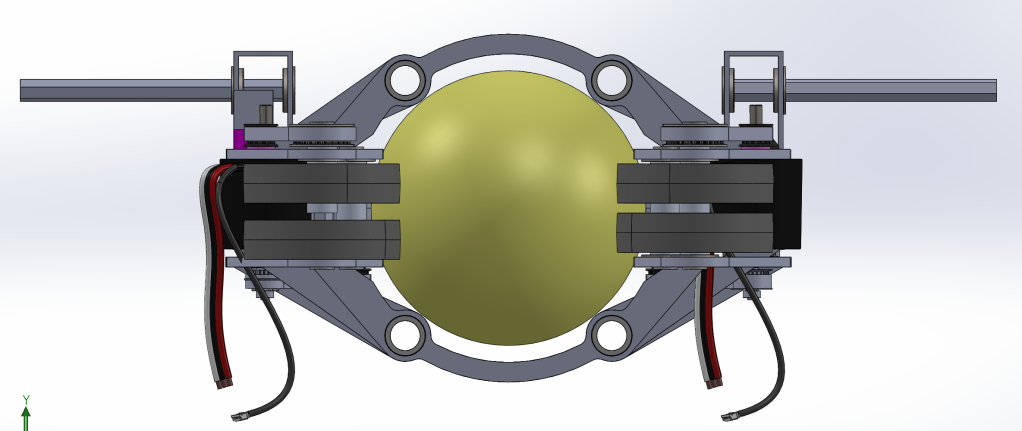

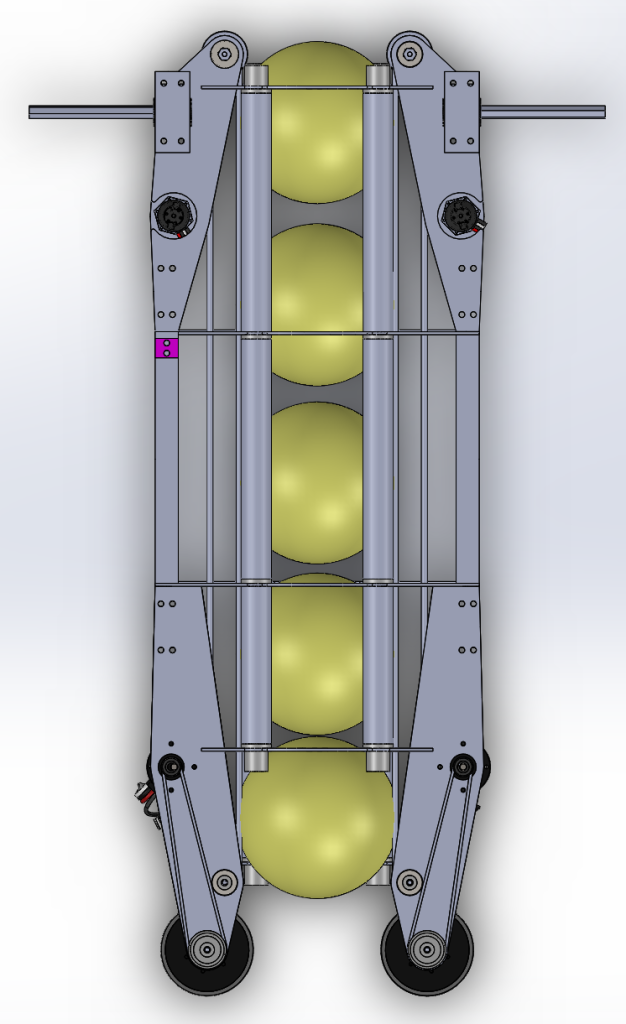

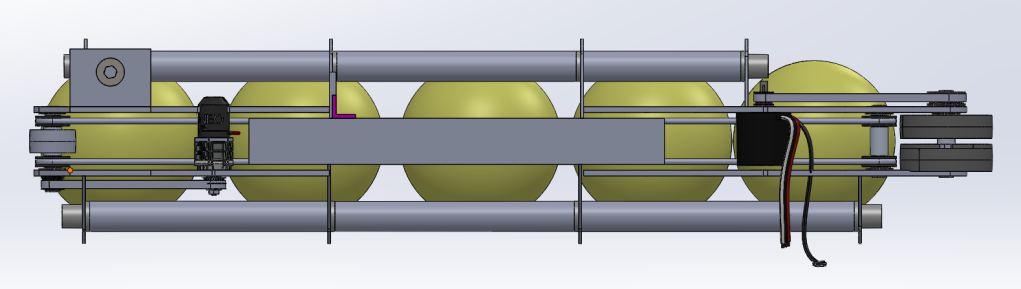

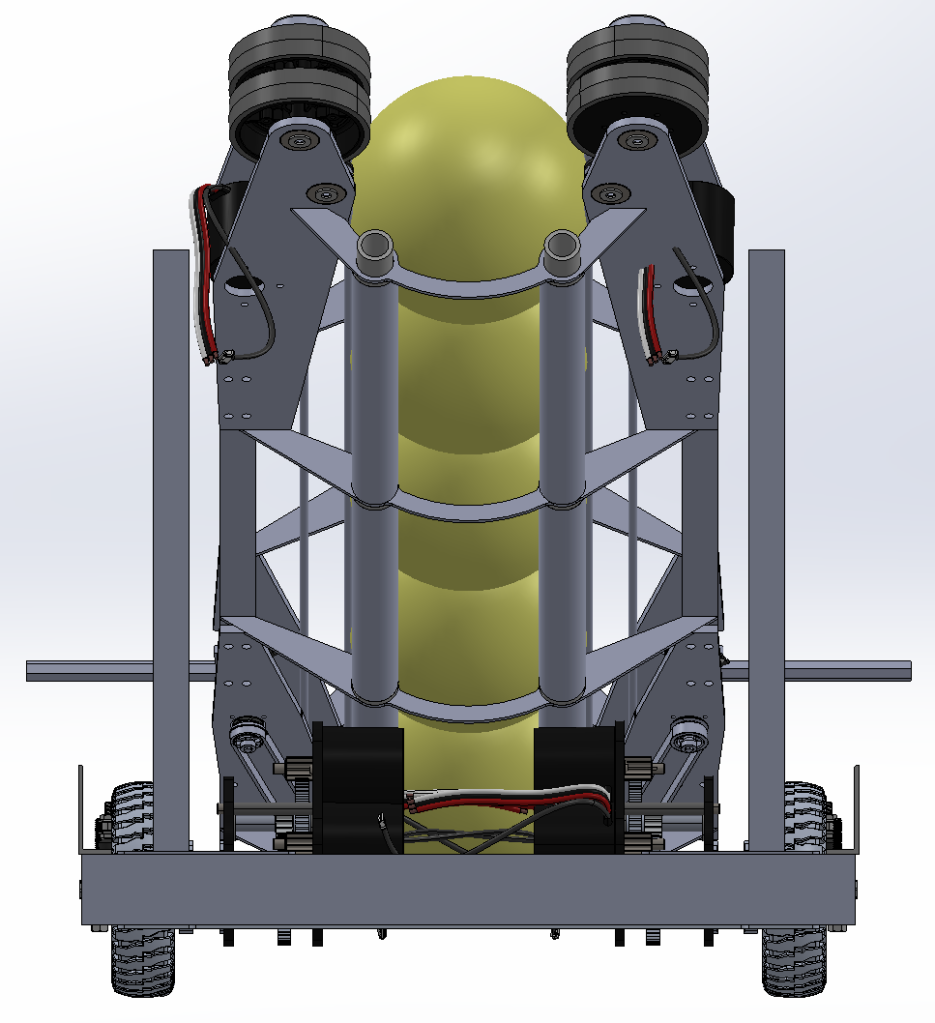

Some pictures of the tube assembly as is now.

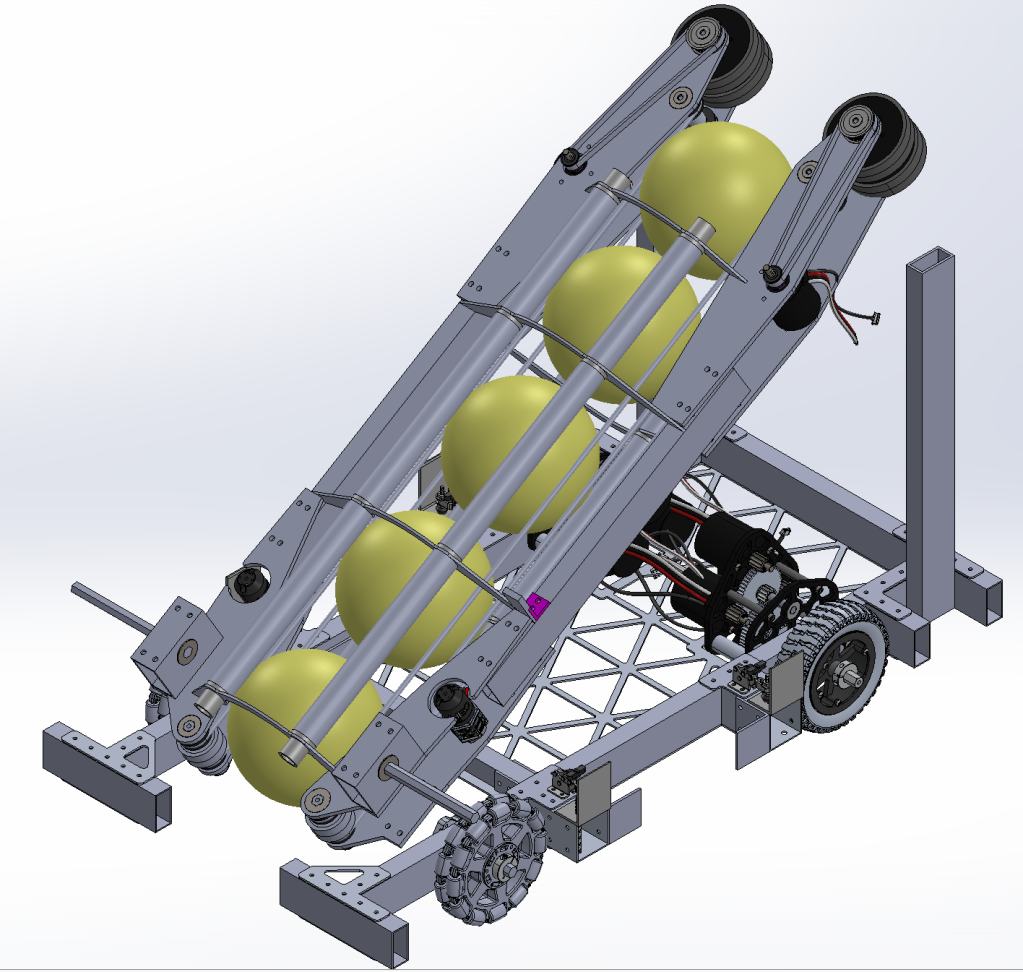

What the full assembly of the robot looks like right now.

Software managed to finish testing with the Falcon 500 motor and get it working after some technical troubleshooting. The electrical test board proved very useful so props to electrical for that. Software is now working on an autonomous and vision system using a modified setup in the drive room (we can't have the full setup since the ceiling isn't high enough). This testing will have to extend a bit past the initial deadline set pre-season, but since there is a good gap of time for them to be able to finish the robot code (drivetrain and controls) as well as work on autonomous, it seems like software should be right on track as well.

Looking forward, finals are upon us and things usually mellow down for that week. Design should however still be able to reach some crucial milestones (the progress made so far will help them have an easier week) and software still needs to continue developing limelight tracking and autonomous. Overall, things seem to be only slightly lagging behind at the end of week one but with some extra pushes we should be able to get right back on schedule.

Design had great progress with the initial stages of CAD. The drivetrain design and ball transfer tube design are almost finished and only a few small additions need to be made. Work on the elevator, intake, and color wheel mechanism will begin soon. Design seems right on schedule to meet the several deadlines they have next week.

Pictures of the drivetrain right now.

Some pictures of the tube assembly as is now.

What the full assembly of the robot looks like right now.

Software managed to finish testing with the Falcon 500 motor and get it working after some technical troubleshooting. The electrical test board proved very useful so props to electrical for that. Software is now working on an autonomous and vision system using a modified setup in the drive room (we can't have the full setup since the ceiling isn't high enough). This testing will have to extend a bit past the initial deadline set pre-season, but since there is a good gap of time for them to be able to finish the robot code (drivetrain and controls) as well as work on autonomous, it seems like software should be right on track as well.

Looking forward, finals are upon us and things usually mellow down for that week. Design should however still be able to reach some crucial milestones (the progress made so far will help them have an easier week) and software still needs to continue developing limelight tracking and autonomous. Overall, things seem to be only slightly lagging behind at the end of week one but with some extra pushes we should be able to get right back on schedule.

Comments

Post a Comment